The camera, powered by customised Machine Learning software, allows the pig farmer to determine the exact time to ship the animals. Data Respons Solutions has contributed with a customised robust single board computer.

dol-sensors is a Danish AgriTech company that designs, produces, and markets intelligent capacitive sensors, climate sensors and management sensors such as weighing components and cloud digital services for livestock farming & the feed industry. dol-Sensors has 40+ years of experience in the agricultural sensor industry, producing more than 250 000 sensors a year.

Livestock farmers and integrators struggle to optimise their management strategy due to lacking weight parameter. This solution allows the farmer to monitor daily weight and weight gain, optimise feeding, sorting and shipping strategy, in general making production more cost efficient, effective, and sustainable.

Powered by tailor-made Machine Learning software the camera allows the pig farmer to determine the exact time to ship the animals. A specially developed and trained Machine Learning algorithm enables the iDOL 65 camera to determine the weight of an animal with 2.7 percent accuracy. This impressive precision has been achieved by training the system on +1 mill. images.

– We are the first AgriTech company to achieve this degree of precision, although the idea to determine the weight of a pig with a camera has been around for about 20 years. Training the Machine Learning algorithm has been the Achilles heel of other attempts to develop similar systems, says Kartheeban Nagenthiraja, CEO of dol-sensors.

According to Kartheeban Nagenthiraja a vision system can make a significant difference for the pig farmer, both in deciding what compound feed to use, and to predict when the animals have gained the correct weight to be shipped to the slaughterhouse.

Collecting enough data to train the algorithm to perform well has been the main challenge. It’s fairly easy to get visual data from for instance 15 animals, but this will get you nowhere. When we began working on the camera software three years ago, we put a lot of thought into how to provide the right data. Not only do you need a lot of images. You need to know the exact weight of the animal and attach it to the right image, Kartheeban Nagenthiraja explains.

The dol-sensors development team came up with a solution and attached an ear mark with an RFID chip on a much larger quantity of pigs and placed a camera and an RFID reader close to the pigs feeding system. Furthermore they installed a scale with another RFID reader to determine the weight of each animal. This setup allowed them to perform automatic data collection of both visual and weight data and connect the both.

– Our goal was to achieve 3 percent precision, meaning that the system should be able to assess a 100 kg animal to weigh between 97 and 103 kg. We achieved that goal and currently our precision is down to 2.7 percent. We are working on fine-tuning our algorithm to make it even more precise and have designed the camera to be able to update it remotely with new software versions.

Just like the software, the hardware wasn’t that straightforward. First and foremost, the camera had to be designed to withstand the environment in a pigpen. Dust and ammonia required the electronics to be completely encapsulated and as an average pig farmer will need approximately 30 to 40 cameras, the device itself had to be cost effective but made with good quality industrial-grade components.

– We started out with a cheap camera and an electronics board bought from Alibaba, development engineer and project manager at dol-sensors, Martin Svalgaard explains.

Furthermore, the development team worked closely together with a software engineer from Data Respons Solutions to connect the hardware drivers to the application layer. The device uses NXP’s configuration of a Linux distribution. Data Respons Solutions has also contributed to securing the iDOL 65 camera, to prevent unauthorised access.

However, when developing the device, the dol-sensors’ engineers had to solve a few unexpected problems. Namely fly droppings. Flies are attracted to warm places, and as the device heats up while operating, tiny black dots of fly droppings covered the lens and reduced the performance of the camera.

– We changed the layout of the electronics, so that the area around the camera lens no longer heats up and won’t attract flies anymore. Problem solved, Martin Svalgaard explains.

According to dol-sensors, a pig farmer using the full potential of the iDOL 65 camera system will be able to make an additional profit of DK 70. (0,90 euros) per pig.

Additional profit comes from both being able to ship livestock at the optimal time and weight, and from optimising various other processes, such as determining how and when to adjust compound feed.

In the future, the dol-sensors’ development team will look into using the collected data to not only determine a pig’s weight, but also determine its wellbeing, for instance by analysing movement patterns and other parameters.

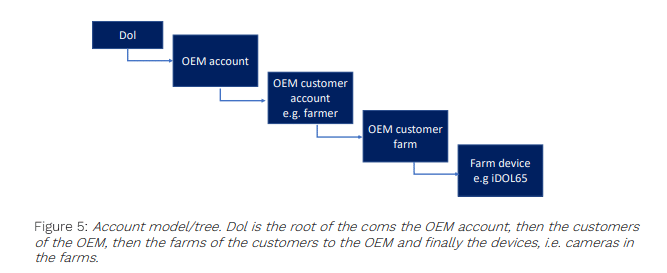

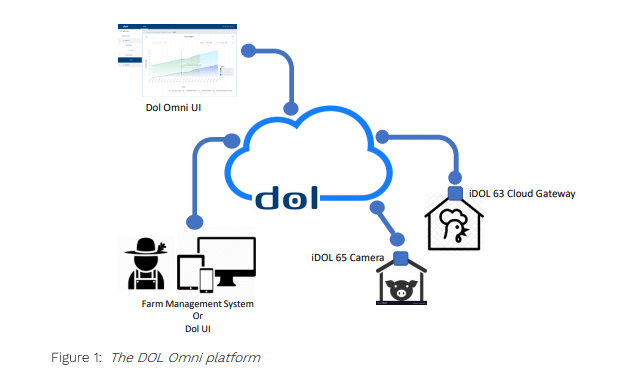

dol-sensors plan on selling around 5 000 cameras over the coming 5 years, to incorporate into their own farm management system and as an OEM product for other integrators in the farm management industry.